.jpg)

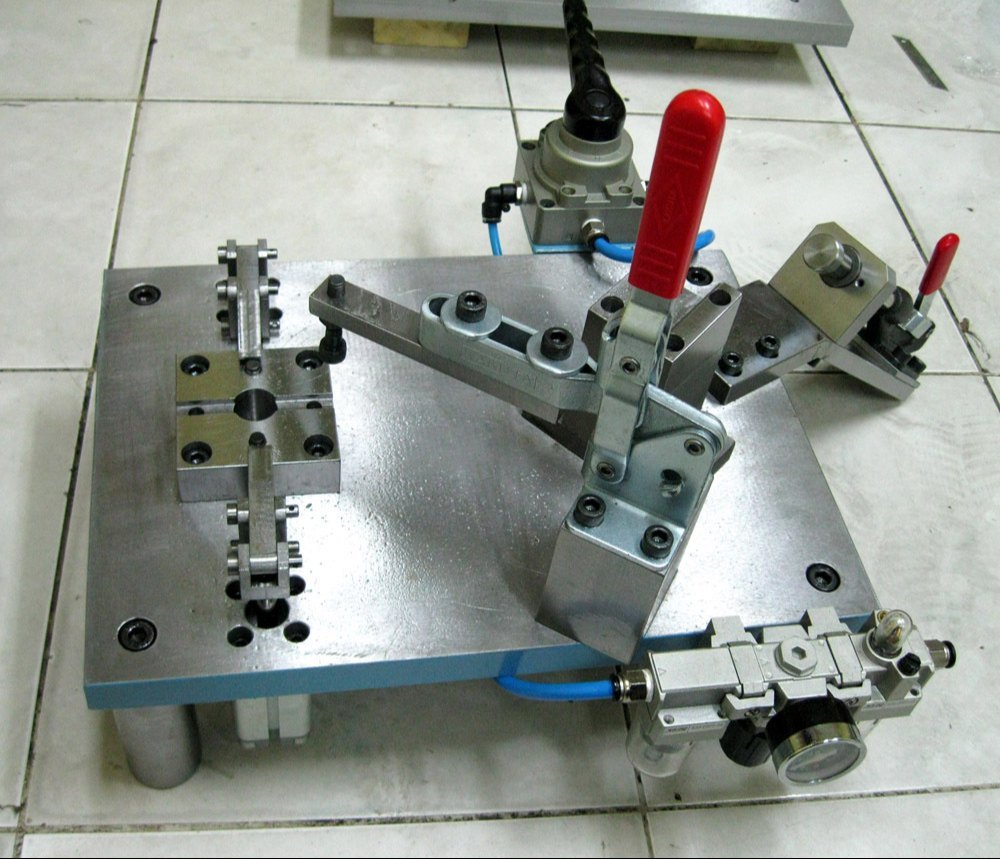

We are taking this opportunity to introduce ourselves as a manufacture of all kinds of Sheet Metal Cutting Dies, Jig Fixtures & Precision Tool Room Engineering Job Works. We are willing to keep a permanent tie up with your reputed organization, which is honor to us.

Tryambak Engineers is one of the leading manufacturers of all kinds of sheet metal cutting dies. Jig fixtures & Precision tool room engineering job works. The efficient project management and technical support services at customer's location guarantees the successful execution of each project.

projects

Factories

Employees

Manufacturer of all kinds of sheet metal cutting dies, jig fixtures. All types of precision tool room engineering jobs with any NC/VMC profile machining.

Any Type of Round Part till Φ - 500 And □ till (400 X 400) Can Make turning in house .

Manufacturing engineering is considered to be a subdiscipline of industrial engineering/systems engineering and has very strong overlaps with mechanical engineering.

Jigs and fixtures are specialised tools used in manufacturing to secure workpieces and guide cutting or shaping tools, ensuring precision and repeatability in production processes. These specialised devices play a pivotal role in securing workpieces, guiding cutting tools, an

The automation of rolling line components manufacturing involves integrating advanced technologies and machinery to produce rolling components such as rollers, shafts, and bearings efficiently and accurately

Perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi archite.

Manufacturing processes in mechanical engineering can be divided into metal shaping, metal joining, metal cutting, and metal finishing. It also includes welding, metallurgy, solidification, and metal forming processes.