Driling

Drilling services are essential in the manufacturing industry for creating holes in various materials to accommodate fasteners, components, or other features.

Safety considerations are paramount in drilling operations to prevent accidents, injuries, and equipment damage. Operators must adhere to safety protocols, wear appropriate personal protective equipment (PPE), and follow established procedures for machine setup, operation, and maintenance. Additionally, drilling processes must comply with relevant industry regulations and standards to ensure product safety and compliance.

-

Types of Drilling Operations

There are several types of drilling operations, including twist drilling, counterboring, countersinking, reaming, tapping, and deep hole drilling. Each type serves specific purposes and produces holes with different characteristics. -

Precision and Accuracy

Modern drilling equipment is capable of achieving high levels of precision and accuracy, allowing for the creation of holes with tight tolerances and consistent dimensions. This is crucial for ensuring the proper fit and alignment of components in assembly processes. -

Material Compatibility

Drilling services can be tailored to suit the properties of different materials, including hardness, toughness, and brittleness. Specialized drilling techniques and tooling are employed to optimize performance and maximize tool life when drilling various materials. -

Production Efficiency

Drilling services contribute to production efficiency by enabling the rapid creation of holes in workpieces, reducing overall manufacturing cycle times. Automated drilling systems and CNC machining centers further enhance productivity by streamlining drilling processes and minimizing manual intervention. -

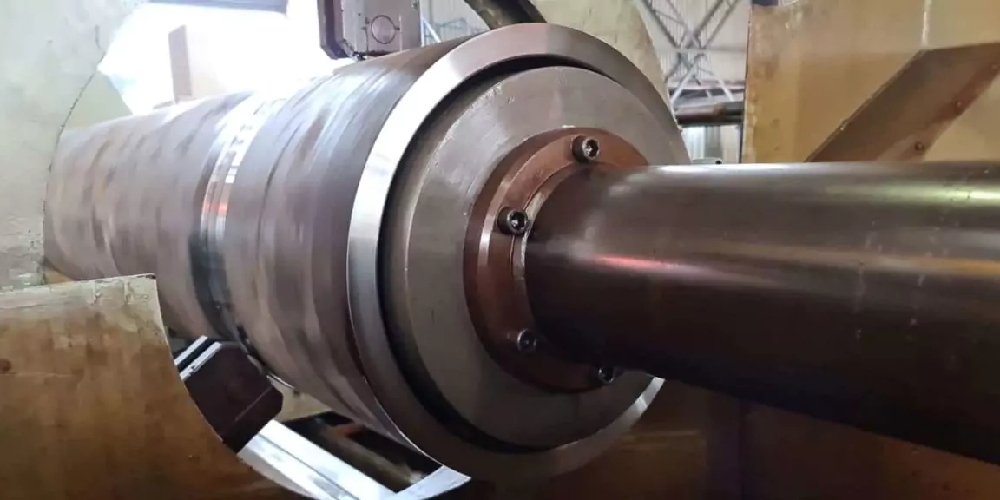

Tooling and Equipment

Drilling operations require specialized tools and equipment, including drill bits, drilling machines, drilling rigs, and accessories such as coolant systems and chip evacuation mechanisms. Proper selection, maintenance, and calibration of drilling equipment are essential for achieving optimal results. -

Hole Quality and Surface Finish

Drilling services can produce holes with a range of surface finishes, from rough to smooth, depending on the application requirements. Secondary processes such as deburring, chamfering, and honing may be employed to improve hole quality and surface finish as needed.