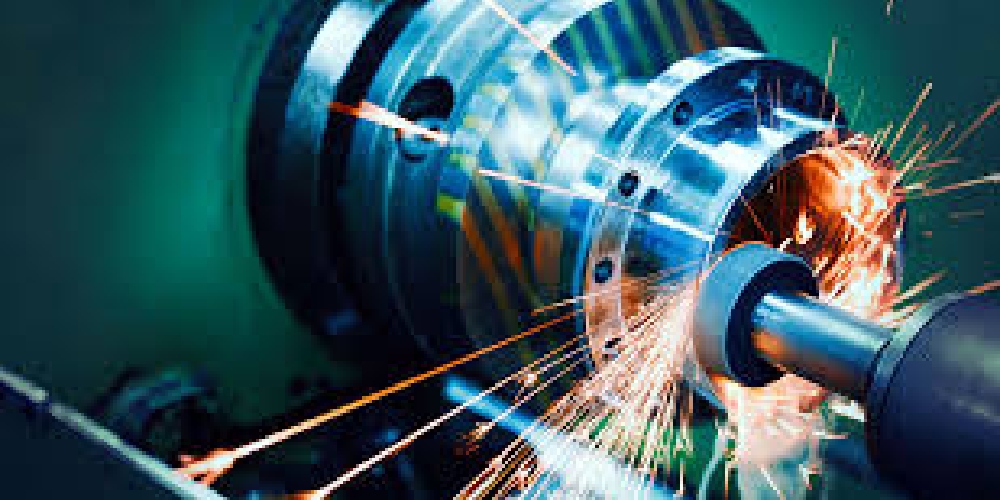

Grinding

Grinding is a fundamental process in the manufacturing industry, crucial for producing precision components with tight tolerances and high-quality surface finishes. Grinding is a material removal process where abrasive particles are used to remove excess material from a workpiece. It's particularly effective for hard materials like metals and ceramics.

-

Precision Machining

Grinding is a machining process that utilizes abrasive cutting to remove material from a workpiece. It is capable of achieving tight tolerances and high surface finishes, making it ideal for producing precision components used in various industries such as automotive, aerospace, medical, and tooling. -

Types of Grinding

There are various types of grinding processes employed in the manufacturing industry, including surface grinding, cylindrical grinding, centerless grinding, and internal grinding, among others. Each type of grinding process is suited for specific applications and workpiece geometries. -

Material Versatility

Grinding services are used with a wide range of materials, including metals (such as steel, aluminum, and titanium), ceramics, composites, and plastics. This versatility makes grinding suitable for diverse manufacturing requirements. -

Surface Finish Enhancement

Grinding can improve surface finish quality by removing surface imperfections, burrs, and irregularities, resulting in smoother and more precise surfaces. This is essential for parts requiring tight sealing, friction reduction, or aesthetic appeal. -

Tooling and Equipment

Grinding services require specialized equipment such as grinding machines, grinding wheels, and fixtures designed for specific applications. Regular maintenance and calibration of grinding equipment are essential to ensure optimal performance and accuracy. -

Quality Assurance

Quality control measures are integral to grinding services to ensure that machined components meet specified requirements. Inspection techniques such as dimensional metrology, surface roughness measurement, and non-destructive testing are employed to verify part quality and conformance.