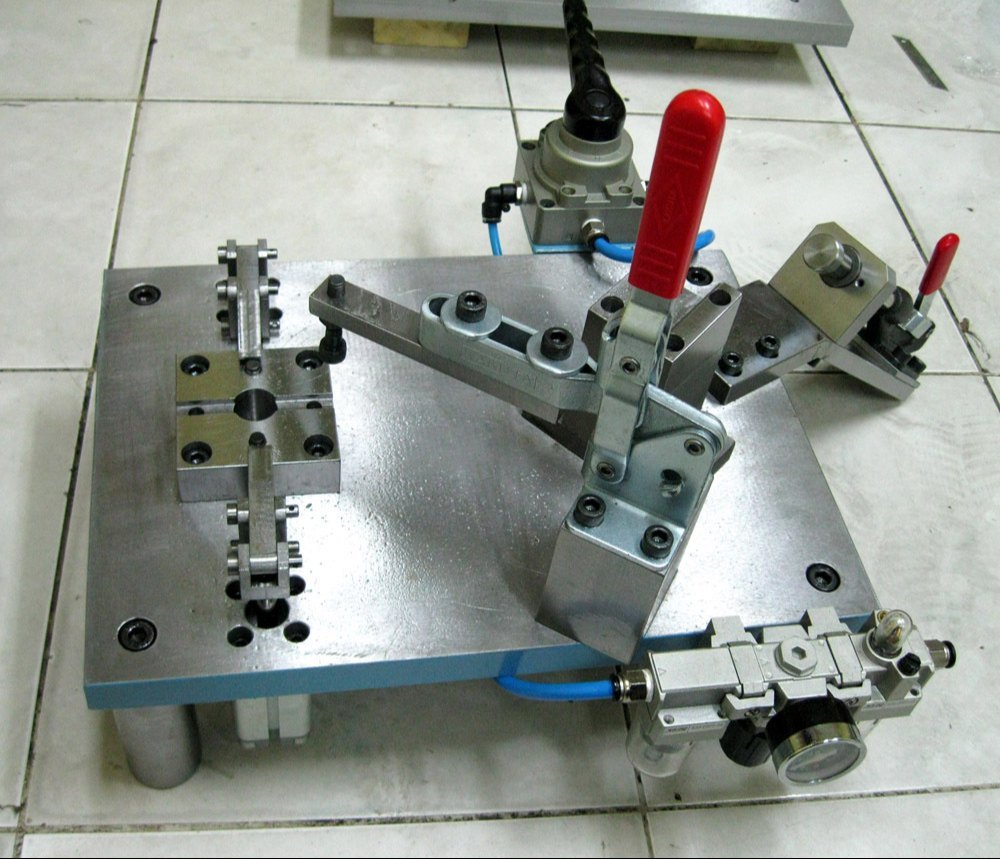

JIG AND FIXTURES

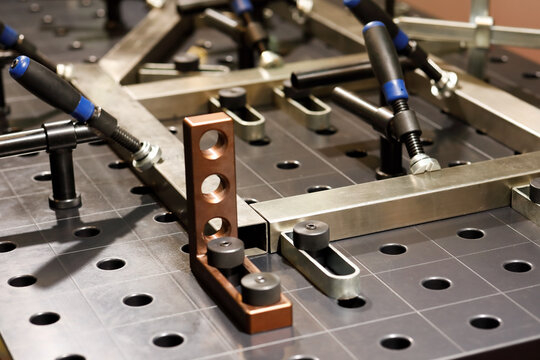

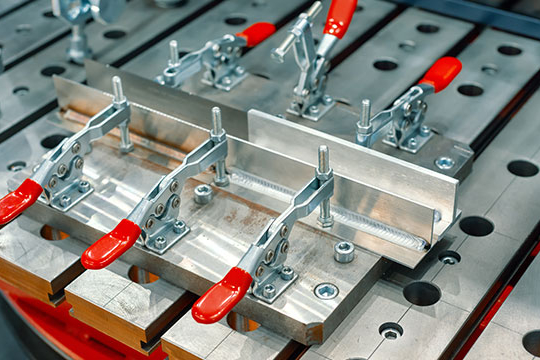

Jigs and fixtures are specialised tools used in manufacturing to secure workpieces and guide cutting or shaping tools, ensuring precision and repeatability in production processes. These specialised devices play a pivotal role in securing workpieces, guiding cutting tools, and ensuring the repeatability of complex operations. They are tailored to the specific needs of production, facilitating tasks ranging from drilling and welding to milling and assembly. They not only enhance the accuracy and quality of finished products but also significantly reduce production time, making them invaluable assets in modern manufacturing processes

- Increased Productivity

- Enhanced Quality

- Cost Efficiency

- Minimizes handling and improves ergonomics.

Process Of Project

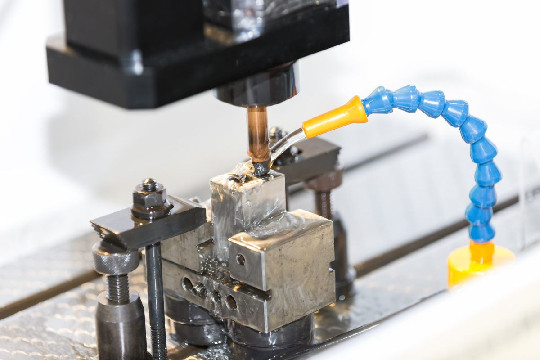

Manufacturer of all kinds of sheet metal cutting dies, jig fixtures. All types of precision tool room engineering jobs with any NC/VMC profile machining.

-

- Requirement Analysis :

- Collect detailed information about the part or process the jig or fixture will be used for.Determine key parameters such as tolerances, material specifications, and production volume.

-

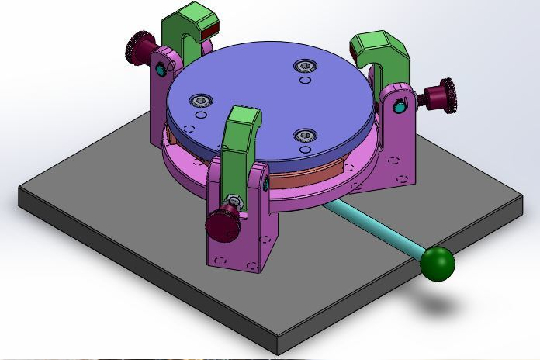

- Design Phase :

- Create detailed plans and specifications for the jig or fixture.

-

- Material Selection :

- Choose appropriate materials that meet the design specifications and operational requirements.

-

- Machining and Fabrication :

- Manufacture the jig or fixture components according to design specifications.

-

- Inspection and Quality Control :

- Ensure the manufactured jig or fixture meets all design specifications and quality standards.

-

- Trial and Validation :

- Validate the performance of the jig or fixture in actual manufacturing conditions.

-

- Final Production and Implementation :

- Begin full-scale production using the validated jig or fixture.

-

- Maintenance and Continuous Improvement :

- Ensure the jig or fixture remains in optimal working condition and continues to meet production requirements.

-

- Conclusion :

- The manufacturing process for jigs and fixtures is a meticulous and iterative process that ensures these tools meet the exacting standards required for precision manufacturing. From initial design to final implementation, each step is crucial for creating jigs and fixtures that enhance productivity, accuracy, and efficiency in the manufacturing process.

Component

Manufacturer of all kinds of sheet metal cutting dies, jig fixtures. All types of precision tool room engineering jobs with any NC/VMC profile machining.