Bendsaw

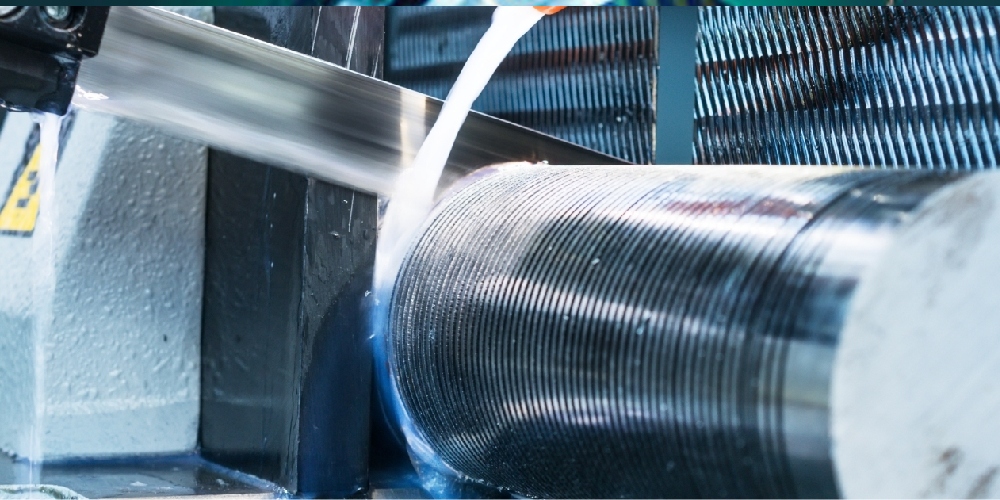

Band saws play a crucial role in the manufacturing industry, particularly in metalworking and woodworking processes.

Band saws are versatile cutting tools capable of cutting various materials, including metals, plastics, and wood. They are widely used for straight, curved, or irregular cuts in workpieces of different shapes and sizes.

-

Precision Cutting

Band saws offer high precision and accuracy in cutting, making them suitable for producing parts with tight tolerances. They can achieve smooth, clean cuts with minimal material wastage, enhancing efficiency and cost-effectiveness. -

Types of Band Saws

There are different types of band saws used in manufacturing, including horizontal band saws and vertical band saws. Horizontal band saws are commonly used for cutting large workpieces or bundles of materials, while vertical band saws are ideal for cutting intricate shapes and contours. -

Efficiency and Productivity

Band saws are known for their efficiency and productivity, allowing for rapid material removal and high throughput in manufacturing processes. They can handle a wide range of cutting tasks, from rough cutting to finishing operations, with minimal operator intervention. -

Automation and Integration

Modern band saws often incorporate automation features such as programmable controls, automatic feed systems, and material handling devices. This enhances productivity, reduces operator fatigue, and improves overall efficiency in manufacturing operations. -

Material Handling

Band saws can be equipped with various material handling accessories such as roller tables, conveyors, and clamping systems to facilitate efficient loading, positioning, and cutting of workpieces. This helps streamline workflow and minimize downtime between cutting operations. -

Customization and Specialization

Band saw services can be customized to meet specific manufacturing needs and applications. Some service providers specialize in niche markets or industries, offering expertise in particular materials, cutting techniques, or production requirements. -

Quality Assurance

Quality control measures are essential in band saw services to ensure that cut parts meet specified requirements. Inspection techniques such as dimensional metrology and visual inspection are employed to verify cut accuracy and surface quality, maintaining consistent quality standards throughout the manufacturing process.