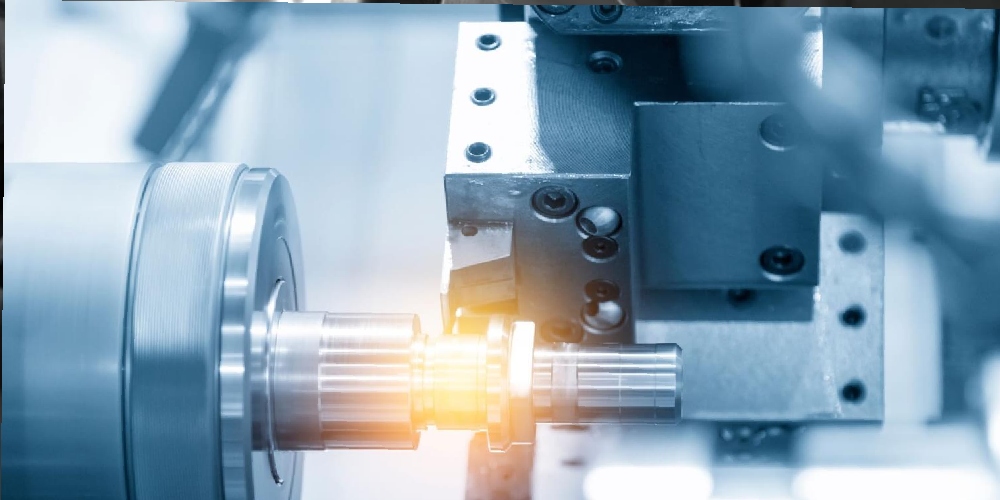

Turning

Turning services in the manufacturing industry refer to the process of shaping cylindrical materials, typically metal, into various components or parts. This process involves rotating a cutting tool while the material is held stationary or rotated on a lathe. Turning services are crucial in manufacturing as they produce precise and symmetrical cylindrical shapes required for a wide range of products across industries.

-

Lathe Operations

Turning services are primarily carried out on lathes, which are machines equipped with a rotating spindle that holds the workpiece and a cutting tool that moves parallel to the axis of rotation. -

Material Compatibility

Turning services are commonly used for metalworking, including materials such as steel, aluminum, brass, and various alloys. However, turning can also be applied to other materials like plastics and wood. -

Types of Turning

There are various types of turning operations, including external turning (machining the outer diameter of a workpiece), internal turning (machining the inner diameter), facing (creating a smooth surface at the end of a workpiece), and taper turning (producing a conical shape). -

Precision and Accuracy

Turning services are valued for their ability to achieve high precision and accuracy, essential for producing components with tight tolerances. -

Automation and CNC

Many turning processes are automated using Computer Numerical Control (CNC) technology, which allows for efficient and repeatable production of parts according to precise specifications. -

Applications

Turning services are utilized in various industries, including automotive, aerospace, electronics, medical devices, and general manufacturing. Parts produced through turning services can range from simple components like shafts and bolts to complex parts such as turbine rotors and engine cylinders. -

Surface Finish and Quality

The surface finish of turned parts can be optimized through proper tool selection, cutting parameters, and post-processing techniques such as polishing or coating.